Custom Flex Sensors: Going Beyond Regular Sensing Capabilities

Struggling to find the right pressure sensor for your invention? Discover the perfect fit with customized flexible sensors. Adapt to any shape or surface, achieving precise sensitivity, durability, and compatibility and bring out limitless innovation, elevating your device’s performance.

What Are They and How Do They Work

Custom Flex Sensors are typically designed based on principles from materials science, engineering, and electronics. The mechanism behind these sensors involves the integration of flexible materials and the manipulation of their electrical properties to detect and measure different physical quantities.

Flexible Substrate

The first key component is a flexible substrate, which can be made of polymers, such as polyimide or polyethylene terephthalate (PET). These substrates provide the flexibility required for conforming to different shapes and surfaces.

Functional Materials

Next, functional materials are deposited or patterned onto the flexible substrate. These materials can include conductive elements like metals (e.g., gold, silver, copper), conductive polymers, or carbon-based materials (e.g., graphene or carbon nanotubes). The choice of materials depends on the desired sensing properties and the intended application.

Sensing Mechanism

The functional materials on the flexible substrate are designed to respond to specific stimuli, such as pressure, strain, temperature, humidity, or chemical changes. The changes in these stimuli induce alterations in the electrical properties of the sensing materials.

Electrical Circuitry

The sensing materials are connected to electrical circuitry, which can include electrodes, conductive traces, or interconnects. These elements allow for the measurement and transmission of the electrical signals generated by the sensing materials.

Signal Processing

The electrical signals obtained from the sensors are processed using electronic circuits or microcontrollers. This step involves amplifying, filtering, and analyzing the signals to extract the desired information related to the physical quantity being measured.

Output and Integration

Finally, the processed electrical signals are used to generate an output, which can be in the form of data, visual feedback, or control signals for other systems. Custom Flex Sensorss can be integrated into a wide range of applications, including wearable devices, healthcare monitoring systems, robotics, human-machine interfaces, and gigantic industrial machinery.

The Principle Behind Custom Flex Sensors

One common principle is the strain gauge effect. In this case, the flex sensor consists of a flexible substrate with a conductive material, such as metal or conductive polymer, patterned onto it. As the sensor is bent or flexed, the sensing material experiences strain, causing its electrical resistance to change. This change in resistance can be measured and correlated to the degree of bending or flexing.

Another principle used is capacitive sensing. Flex sensors based on capacitance measure the change in capacitance between two conductive layers as the sensor is bent. The distance between the conductive layers changes with the flex, altering the capacitance. By measuring this change, the degree of bending or flexing can be determined.

It’s important to note that these principles are not limited to flex sensors and can be applied to other types of sensors as well.

The customization aspect of flex sensors comes from the selection of materials, the design of the sensor structure, and the integration with appropriate signal conditioning and processing techniques.

These elements allow for the customization of flex sensors to meet specific application requirements and achieve desired sensitivity, accuracy, and response characteristics.

Advancements in Custom Flex Sensors

The field of custom flex sensors continues to evolve rapidly, driven by ongoing advancements in materials, manufacturing techniques, and sensor technology. Researchers and engineers are constantly exploring new possibilities to enhance the performance and functionality of these sensors, opening up exciting opportunities for the future.

Improved Sensing Capabilities

Scientists are actively working on improving the sensitivity and accuracy of custom flex sensors. By incorporating advanced materials and innovative design approaches, we aim to develop sensors that can detect even the smallest changes in their environment. This enhanced sensitivity will enable precise measurements in various applications, such as detecting minute movements in robotics or monitoring subtle changes in medical conditions.

Integration with Artificial Intelligence

The integration of custom flexible sensors with artificial intelligence (AI) is an area of significant interest. By combining sensor data with AI algorithms, it becomes possible to extract meaningful insights and make intelligent decisions in real-time.

For example, in healthcare, AI-powered algorithms can analyze sensor data to identify patterns or anomalies, aiding in early disease detection or personalized treatment plans. In autonomous vehicles, customized flex sensors, along with AI, can enable advanced driver assistance systems, enhancing safety and improving overall driving experience.

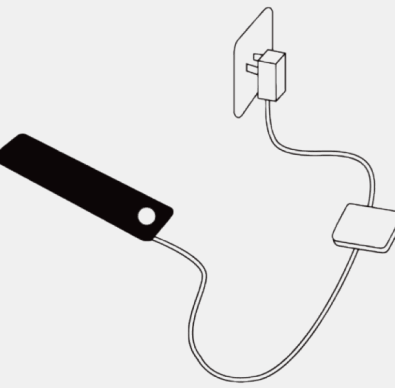

Energy Harvesting

This advancement would not only make the sensors more sustainable but also enhance their versatility by removing the constraints of battery life. Energy harvesting techniques, such as piezoelectric or thermoelectric energy conversion, can potentially enable self-powered sensors that operate indefinitely, paving the way for applications in remote locations or hard-to-reach environments

Wearable Technology

For example, in sports and fitness, customized flex sensors embedded in clothing or accessories can provide real-time monitoring of biometric data, helping athletes track their performance and optimize training.

In healthcare, wearable devices equipped with customizable sensors can provide continuous health monitoring and early warning systems, alerting individuals and healthcare professionals to potential health concerns.

Challenges and Considerations

As with any emerging technology, there are challenges that need to be addressed to fully realize the potential of custom flex sensors.

Additionally, ensuring the reliability and consistency of sensor performance across large-scale production can be a complex task.

Another consideration is the standardization of sensor interfaces and communication protocols. As the number of applications and devices incorporating custom flex sensors grows, establishing common standards will facilitate interoperability and compatibility, enabling seamless integration and data exchange between different systems.

Privacy and security also remain critical concerns. As these sensors collect and transmit sensitive data, it is essential to implement robust security measures to protect user information and prevent unauthorized access. Additionally, ethical considerations surrounding data collection, usage, and consent need to be addressed to ensure responsible and transparent deployment of these sensors.

Increase Efficiency in Your Devices and Machines With Flexniss

Custom flex sensors have already made significant strides in revolutionizing the world of sensing technology. However, the journey continues as researchers and engineers push the boundaries of what is possible.

If you’re on the hunt for custom flex sensors that go beyond the ordinary, Flexniss is your partner. We specialize in creating sensors that not only meet your specific needs but exceed your expectations. Our mission is to bring durability, functionality, and versatility into your own custom flexible sensor.

When you choose Flexniss, you’re choosing a company that understands the importance of tailored solutions that perfectly align with your vision. We take pride in our attention to detail and commitment to delivering high-quality sensors that withstand the test of time.

With our custom flex sensors, you can achieve the perfect balance of performance and adaptability.

Connect with Flexniss today and let us bring durability, functionality, and versatility to your custom flexible sensor!