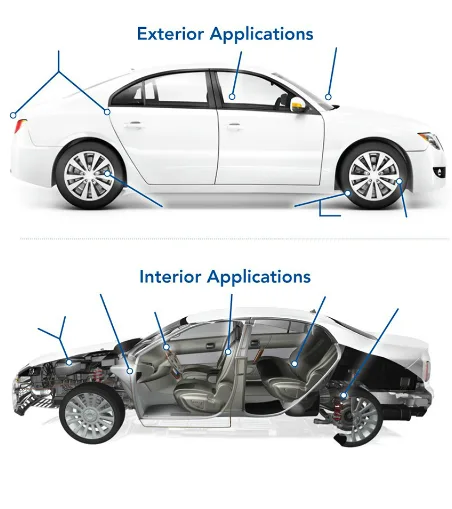

Automotive Pressure Sensors for Precision Engineering and Safety

Optimize design, safety, and comfort across critical vehicle components with Flexniss’s advanced automotive pressure sensors.

Automotive Pressure Sensors for Precision Engineering

Flexniss offers cutting-edge automotive pressure sensors designed to meet the rigorous demands of the automotive industry. From improving passenger comfort to optimizing safety and performance in critical vehicle components, our automotive pressure sensors provide precise pressure analysis for a variety of applications.

Automotive Seat Pressure Sensors

Intelligent cockpit's non-camera fatigue driving monitoring and auxiliary reminder

Every year, approximately 500,000 people die in traffic accidents worldwide, and more than 60% of these accidents are related to fatigued driving. Fatigue driving monitoring and auxiliary reminders can be achieved by using flexible sensors placed in car seats.

Detecting the pressure conditions of dummies during car crash tests and simulating the pressure distribution of dummy sitting postures to improve seat design

Flexniss pressure sensors ensure that car seats are designed with both comfort and ergonomic support in mind. By analyzing how pressure distributes across seats, engineers can design seating that provides superior comfort and reduces fatigue during long drives.

Seatbelt unfastened reminder, car engine start detection, car anti-theft assistance reminder.

In 2020, new regulations were introduced for the automotive industry that require vehicles with three seats in the back to be equipped with a seat belt unfastened reminder function. Therefore, integrating the seat belt reminder sensor into the car seats can achieve the function of reminding passengers to fasten their seat belts. Additionally, our flexible sensors can also realize engine start detection and assist in car anti-theft alerts.

Tire Pressure Mapping Sensors

By analyzing tire pressure distribution, our automotive pressure sensors help engineers design tires that perform optimally in terms of traction, control, and wear. This enhances vehicle safety and improves tire longevity.

Brake Pressure Sensors

Our sensors are crucial in testing brake systems by measuring pressure distribution during braking, helping engineers design brake components that maximize safety and control.

Steering Wheel Pressure Sensors

Steering wheel heating and hands-off detection sensors can effectively improve driving safety, and many advanced driver assistance systems (ADAS) have been applied to automobiles. Steering wheel hands-off detection (HOD) is a type of ADAS and also a requirement for L1-L4 level automotive autonomous driving systems. According to United Nations Regulation No. 79, all new vehicles providing lane-keeping assistance systems (LKAS) must be equipped with steering wheel hands-off detection (HOD) functionality. The European Union has also adopted this regulation for new vehicles produced from April 1, 2021. There are various methods for implementing HOD, such as torque detection reuse, optical system detection, capacitive sensing detection, etc. The ams AS8579 is currently a relatively mature capacitive detection solution.

Windshield wiper pressure sensor

The wiper pressure sensor can detect the force distribution between the windshield and the wiper, as well as the force proportion at various positions on the blade, to improve the performance of the wiper.

Rear Spoiler Pressure Sensor

By simulating the pressure distribution of the aerodynamic drag acting on the car's spoiler components during driving, we can optimize the car's aerodynamic drag.

Why Choose Flexniss Sensors for Automotive Applications?

Increased Reliability and Safety

Our sensors provide the data needed to design safer and more reliable automotive components.

Enhanced Comfort and Performance

Design with precision to ensure maximum comfort and performance for your vehicle.

Accurate, Real-Time Data

Get fast and reliable results with real-time pressure mapping technology.

Cost-Effective Testing Solutions

Our sensors facilitate efficient, repeatable testing methods that save on development costs and time.

How Flexniss Automotive Pressure Sensors Work

Process Overview:

- Apply sensors to the desired vehicle component.

- Collect real-time pressure data throughout the testing process.

- Analyze the data using Flexniss software for detailed insights.

- Make informed design changes based on the results.