Micro-Nano Sensor YD-SF23-600

Nano-thin

Energy Saving

Wide Detection

Customizable Size

Quick Response

Excellent Stability

The YD-SF23-600 is constructed using a combination of piezoelectric and piezoresistive materials, arranged in a composite structure.

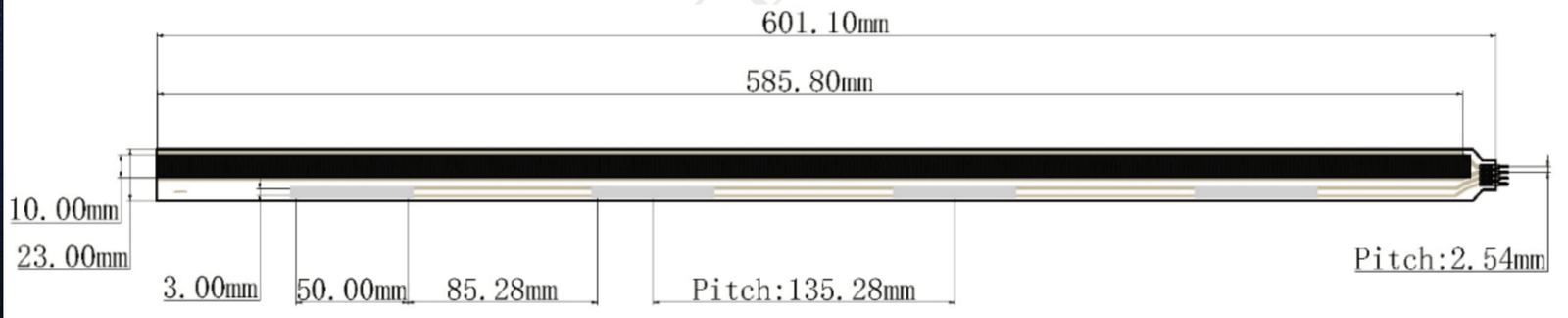

| Product Dimensions | |

| Overall Length | 601.10 mm |

| Overall Width | 23 mm |

| Piezoresistive Sensing Area (length x width) | 585.80 mm x 10 mm |

| Piezoelectric Sensing Area (length x width) | 50 mm x 3 mm |

| Piezoelectric Sensing Unit Number | 4 |

| Pin Spacing | 2.54 mm |

| Performance Indicators: Pressure Sensing Component | |

| Measuring Range | 0~5kg |

| Thickness | <0.3 mm |

| Pressure Response Point * | 50 g |

| Repeatability | +10% (50% load) |

| Consistency Note | 2 +15% |

| Hysteresis | +10%(RF+ – RF-) / RF+ |

| Durability | >1 million times |

| Initial Resistance | >10MΩ (no load) |

| Response Time | ><1 ms |

| Recovery Time | <15 ms |

| Test Voltage | DC 3.3V (typical value) |

| Working Temperature | -20°C ~ 60°C |

| Electromagnetic Interference | None |

| Electrostatic Discharges | Not Sensitive |

| Performance Indicators: Piezoelectric Component | |

| Film Thickness | 8-10μm |

| Constant | d33 18-30 pC/N |

| Capacitance | 1.5-3.0 nF |

| Frequency Band | <100 MHz |

| Connection Method | Terminal Connection |

Our sophisticated program algorithm guarantees precise calibration, resulting in a remarkable level of consistency. Following calibration, the typical consistency error is within a range of ±15%, ensuring reliable and accurate performance.

Micro-Nano Sensor YD-SF23-600

The Flexniss YD-SF23-600 is our state-of-the-art integrated high-sensitivity flexible micro-nano sensor that is less than 0.3mm thick.This innovative two-in-one composite sensor combines the power of piezoresistive and piezoelectric technologies, enabling accurate detection of pressure distribution and achieving dynamic response with highly sensitive signal capture.

Piezoelectric Sensor

The piezoelectric component of the sensor is responsible for converting mechanical stress or pressure into an electrical charge. When a force is applied to the sensor, the piezoelectric material generates an electric potential difference due to the deformation it undergoes. This generated charge is proportional to the applied force, allowing for accurate pressure or force measurements.

Piezoresistive Sensor

The piezoresistive component of the sensor consists of materials that exhibit changes in electrical resistance in response to mechanical strain. As the sensor deforms under pressure, the piezoresistive material experiences strain, which alters its resistance. This change in resistance can be measured and correlated to the applied force or pressure.

The composite piezoelectric and piezoresistive sensors provide a comprehensive and accurate sensing solution for applications requiring precise measurements of pressure, force, or strain.

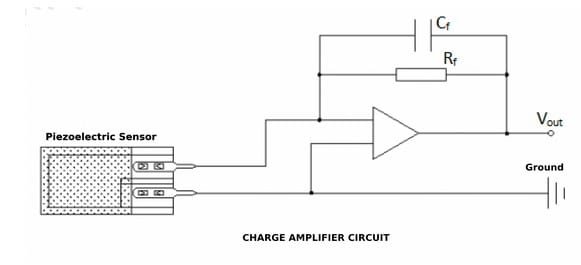

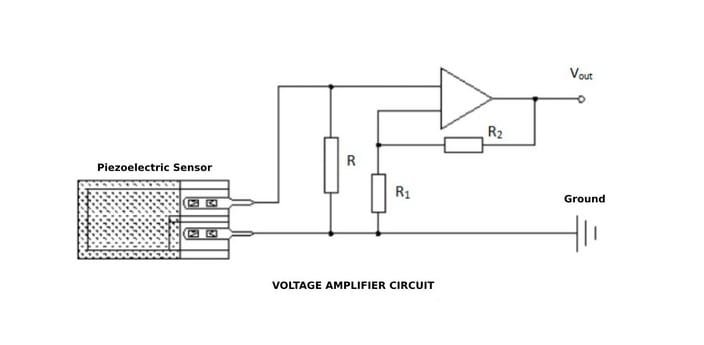

To amplify the electrical signals and optimize signal transmission and processing, we recommend using a high input preamplifier with the YD-SF23-600 composite nano-sensor. A voltage generator or a charge generator can be utilized.

An inherent advantage of using a charge amplifier is its capability to maintain a stable output voltage, regardless of the length of cables connecting the piezoelectric film sensor to the electronic circuitry. This attribute ensures that the output voltage remains unaffected by the capacitance of the cables, enabling consistent signal transmission.

Furthermore, the charge amplifier effectively minimizes charge leakage induced by parasitic capacitance surrounding the sensor. By reducing charge leakage, the charge amplifier enhances the accuracy and reliability of measurements, resulting in precise and dependable data acquisition.

On the other hand, the advantages of voltage amplifiers become apparent when considering the influence of ambient temperature. Unlike charge amplifiers, voltage amplifiers exhibit minimal changes in voltage sensitivity across different temperature ranges. Consequently, when connected to a piezoelectric film sensor, a voltage amplifier is less susceptible to temperature-induced variations in sensitivity. This characteristic ensures more stable and reliable measurements, as the impact of temperature fluctuations on the amplifier’s performance is significantly reduced.