Flexible Thin Film Pressure Sensor ZD10-100

Ultra Thin

Flexible Waterproof Casing

Rapid Detection

Lifetime Durability

Customizable Parameters

Easy Signal Detection

Experience durability like never before with the 0.3mm ZD10-100 flexible sensor, proven to withstand over 1 million testing cycles. As pressure is applied, the sensor’s resistance decreases, ensuring accurate pressure detection through a unique pressure-resistance relationship.

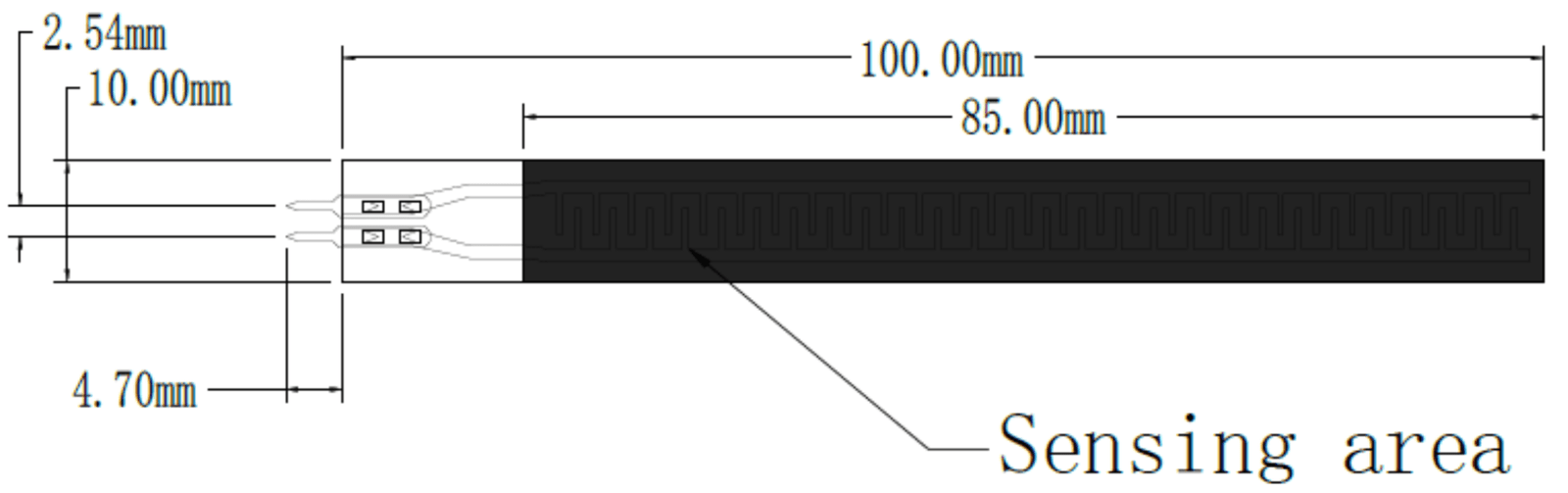

| Product Dimensions | |

| Logo | Size |

| Length | 104.7 mm |

| Width | 10 mm |

| Pin Pitch | 2.54 mm |

| Tolerance | 0.2 |

| Sensing Area | 85 x 10 mm |

| Performance Index | |

| Model | ZD10-100 |

| Range | 0-500 kg |

| Thickness | <0.3 mm |

| Response Point | <50 g |

| Repeatability | <+5% (50% loaded) |

| Consistency | +15% Batch of the same model |

| Hysteresis | +10% (RF+ – RF-)/RF+ |

| Durability | >1 million times |

| Initial Resistance | >10M (Non-Loaded) |

| Response Time | <1 ms |

| Resume Time | <15 ms |

| Test Voltage | Typical Value DC 3.3V |

| Operating Temperature | -20°C-60°C |

| EMI | Nothing Produced |

| ESD | Not Sensitive |

Notes:

- To account for slight batch variations, devices may exhibit minor consistencies. Fear not, as our program algorithm allows for precise calibration, minimizing consistency errors and guaranteeing accurate and reliable performance across all devices.

- To account for slight batch variations, devices may exhibit minor consistencies. Fear not, as our program algorithm allows for precise calibration, minimizing consistency errors and guaranteeing accurate and reliable performance across all devices.

Instruction for Use:

When using the ZD10-100 flexible pressure sensor, it is important to follow these guidelines for optimal performance:

- Place the pressure-sensitive zone of the sensor on a firm, flat surface. Avoid using it on curved or irregular surfaces, as this can cause the sensor to be conductive even without pressure, affecting its response.

- When using the sensor on rigid and hard surfaces where the contact area exceeds the sensitive area, it may result in a small and unstable pressure response. To mitigate this, we recommend attaching a round soft rubber pad to the center of the sensitive area. The pad should have a diameter slightly smaller than the sensitive area, and its surface area should be at least 60% of the sensitive area. This ensures optimal performance and stability during pressure measurements.

- Use double-sided tape to securely fix the sensor on the supporting surface. Ensure that the surface is clean and tidy before applying the tape. We recommend using 3M brand double-sided tape, which provides reliable adhesion.

- Once pressure is applied to the sensor and held, there may be a slight drift in the output resistance value over time, usually within a 5% range. To minimize this error, timing calibration is recommended. During calibration, it is important to match the waiting time after applying pressure with the waiting time in actual applications.

Since the force state of the sensor can vary in different scenarios, we advise users to arrange the sensor according to their specific application needs. Conducting drift parameter testing tailored to their use case will help optimize the sensor’s performance and ensure accurate measurements.

By following these guidelines, you can ensure optimal performance and accuracy when using the ZD10-100 flexible pressure sensor.

Flexible Thin Film Pressure Sensor ZD10-100

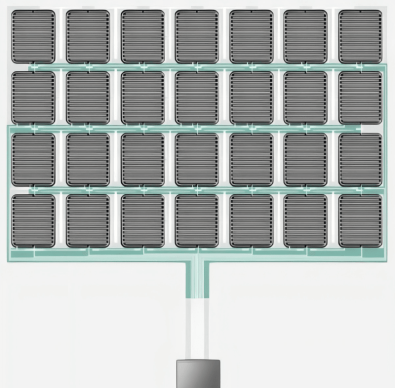

The revolutionary ZD10-100 flexible thin film pressure sensor is a true game-changer with cutting-edge flexible pressure sensor technology. Crafted with independent intellectual property rights, this sensor is meticulously printed on a flexible thin material that boasts exceptional adhesion, remarkable bending resistance, and an extraordinary sensitivity to flexible nano functional materials.

As a resistive sensor, the ZD10-100 flexible film pressure sensor exhibits a decrease in output resistance as pressure is applied to its surface. This pressure-resistance relationship allows for accurate measurement of pressure levels.

Primarily designed for small pressure detection in specific areas, the ZD10-100 sensor boasts an impressively low response point of below 50g. This exceptional sensitivity enables effective detection of pressure triggers and changes on the sensor’s surface.

The applications of the ZD10-100 flexible film pressure sensor are vast and diverse. It finds extensive utility in smart home systems, consumer electronics, automotive electronics, and various other fields where precise pressure detection is essential.

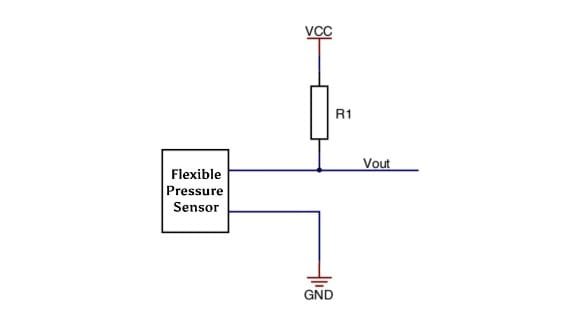

The ZD10-100 reference circuit utilizes partial pressure measurement. It involves connecting the pressure sensor in series with resistor R1, with one end connected to VCC and the other end connected to GND, forming a basic voltage divider circuit. The voltage obtained from the division is then connected to Vout.

This circuit allows the sensor’s output resistance change, which corresponds to the pressure variation, to be converted into a voltage change signal. To cater to different application requirements, it is recommended to select an appropriate load resistance R1 ranging from 1kΩ to 100kΩ. It is suggested that the load resistance be set to 50% of the range pressure corresponding to the sensor’s resistance value.

Vout can be connected to a single-chip microcontroller’s ADC interface to detect pressure levels. Furthermore, the MCU’s external interrupt IO interface can be utilized as a pressure trigger function.