Flexible Thin Film Pressure Sensor MD30-60

Ultra Thin

Power Saver

Swift Response Rate

Wide Detection Range

High Sensitivity

Easy Integration

The MD30-60 series is a thin film pressure sensor that’s <0.6mm thick. Designed with exceptional durability, this tiny but powerful sensor comes packed with functionalities that allow you to provide the best results for your customers.

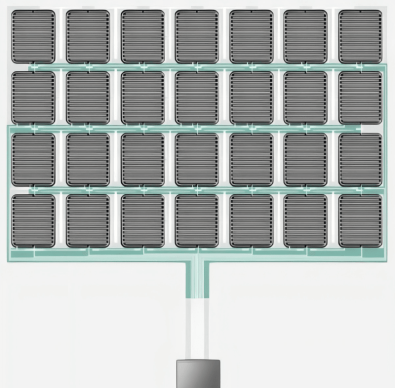

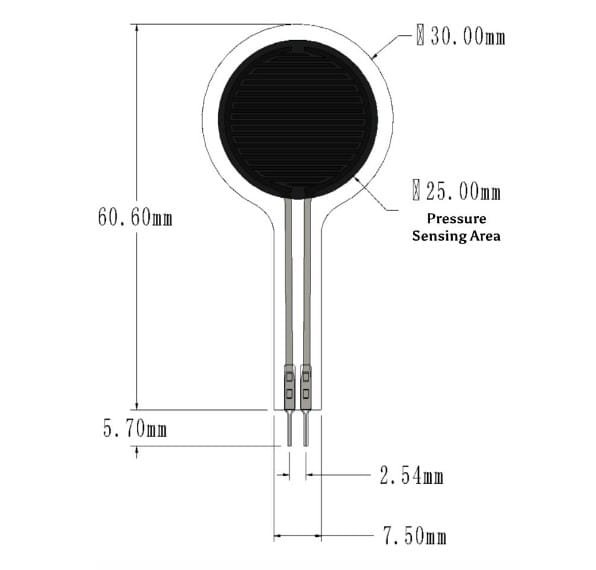

| Product Dimensions | |

| Length | 66.3 mm |

| Width | 30 |

| Sensitive Area | 25 |

| Pin Pitch | 2.54 mm |

| Tolerance | 0.2 |

The MD30-60 comes in four varieties: 10kg, 20kg, 30kg, and 50kg.

| Product Performance | ||||

| Model | 10kg | 20kg | 30kg | 50kg |

| Measuring Range | 0-10kg | 0-20kg | 0-30kg | 0-50kg |

| Thickness | <0.4 mm | <0.6mm | ||

| Response Point 1 | <0.2kg | <0.5kg | ||

| Repeatability | +3% (50% load) | |||

| Consistency Note 2 | +10% | |||

| Hysteresis | +10% (RF+ – RF-)/RF+ | |||

| Durability | >1 million times | |||

| Initial Resistance | >10M2 (no load) | |||

| Response Time | <1 millisecond | |||

| Recovery Time | <15 milliseconds | |||

| Test Voltage | Typical Value DC 3.3V | |||

| Operating Temperature | -20°C – 60°C | |||

| Electromagnetic Interference | Not Generated | |||

| Electrostatic Discharge | Not Sensitive | |||

Notes:

- The response point is the moment when the pressure applied to the sensor gradually increases from 0. It is at this point that the sensor’s resistance decreases to a level below 1MΩ, indicating the initiation of a “response” from the sensor.

- The consistency between devices from different batches will exhibit a slight improvement. With calibration using a program algorithm, the consistency error can be effectively reduced to within a range of ±15%. This ensures a higher level of uniformity and accuracy across the devices, enhancing overall performance and reliability.

Instruction for Use:

When using the FCS-01 flexible pressure sensor, it is important to follow these guidelines for optimal performance:

- Place the pressure-sensitive zone of the sensor on a firm, flat surface. Avoid using it on curved or irregular surfaces, as this can cause the sensor to be conductive even without pressure, affecting its response.

- When using the sensor on rigid and hard surfaces where the contact area exceeds the sensitive area, it may result in a small and unstable pressure response. To mitigate this, we recommend attaching a round soft rubber pad to the center of the sensitive area. The pad should have a diameter slightly smaller than the sensitive area, and its surface area should be at least 60% of the sensitive area. This ensures optimal performance and stability during pressure measurements.

- Use double-sided tape to securely fix the sensor on the supporting surface. Ensure that the surface is clean and tidy before applying the tape. We recommend using 3M brand double-sided tape, which provides reliable adhesion.

- Once pressure is applied to the sensor and held, there may be a slight drift in the output resistance value over time, usually within a 5% range. To minimize this error, timing calibration is recommended. During calibration, it is important to match the waiting time after applying pressure with the waiting time in actual applications.

Since the force state of the sensor can vary in different scenarios, we advise users to arrange the sensor according to their specific application needs. Conducting drift parameter testing tailored to their use case will help optimize the sensor’s performance and ensure accurate measurements.

By following these guidelines, you can ensure optimal performance and accuracy when using the MD30-60 flexible pressure sensor.

Flexible Thin Film Pressure Sensor MD30-60

The MD30-60 thin film pressure sensor is a highly sensitive resistive sensor designed to detect and measure pressure by exhibiting a decrease in output resistance as the pressure applied to its surface increases. This unique characteristic allows for precise and accurate pressure measurement based on a specific pressure-resistance relationship.

With its exceptional performance and versatility, this sensor finds extensive applications across a wide range of industries. In the field of pressure perception, it plays a crucial role in monitoring and controlling pressure-sensitive systems, such as pneumatic machinery, hydraulic systems, and industrial processes.

Practical examples of its application include triggering and detecting the pedal of a balance car, enabling precise control and responsiveness. It also plays a crucial role in cardiopulmonary resuscitation, where it assists in monitoring and adjusting pressure during life-saving procedures. Additionally, it finds application in various scenarios where pressure measurement is essential, such as industrial equipment maintenance, material testing, and environmental monitoring.

With its versatility, accuracy, and reliability, the thin film pressure sensor has become an indispensable component across numerous industries, contributing to advancements in technology, automation, and healthcare.

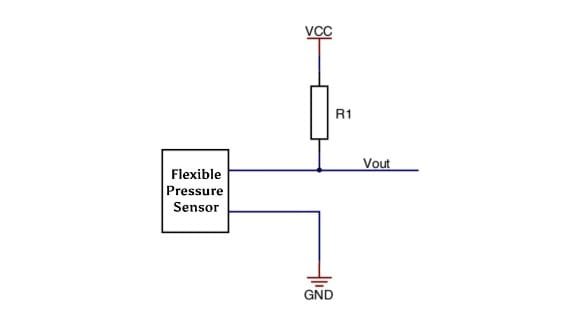

The MD30-60 pressure sensor utilizes the partial pressure method for measurement. It is connected in series with resistor R1, with both ends connected to VCC and GND, forming a basic voltage dividing circuit. The voltage obtained from the division is then connected to Vout.

The change in the sensor’s output resistance, corresponding to the change in pressure, can be converted into a voltage change signal. To meet specific application requirements, an appropriate load resistor R1 should be selected. Typically, a range of 1kΩ to 100kΩ is recommended, with the load resistance ideally being 50% of the pressure range’s corresponding resistance value.

Vout is connected to the ADC interface of the microcontroller, enabling voltage detection. Additionally, it can be connected to the external interrupt IO port of the MCU, allowing for the utilization of the pressure trigger function.