Flexible Film Pressure Sensor ZNS-01

Extremely Thin

Quick Response

20 Pressure Points

Fast Results

Customizable

Quick Pressure Recognition

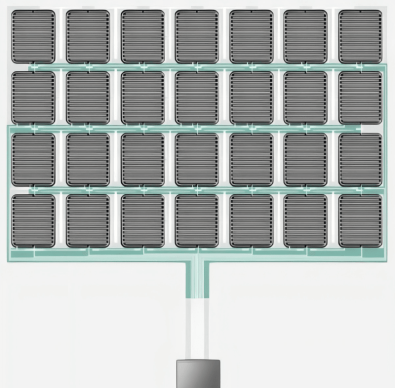

Crafted with precision, the ZNS-01 incorporates state-of-the-art technology, featuring 0.3mm thick flexible film pressure sensors strategically positioned across the palm area. With a total of 20 highly sensitive pressure points meticulously distributed, this pressure sensor technology delivers unparalleled accuracy and responsiveness in pressure detection.

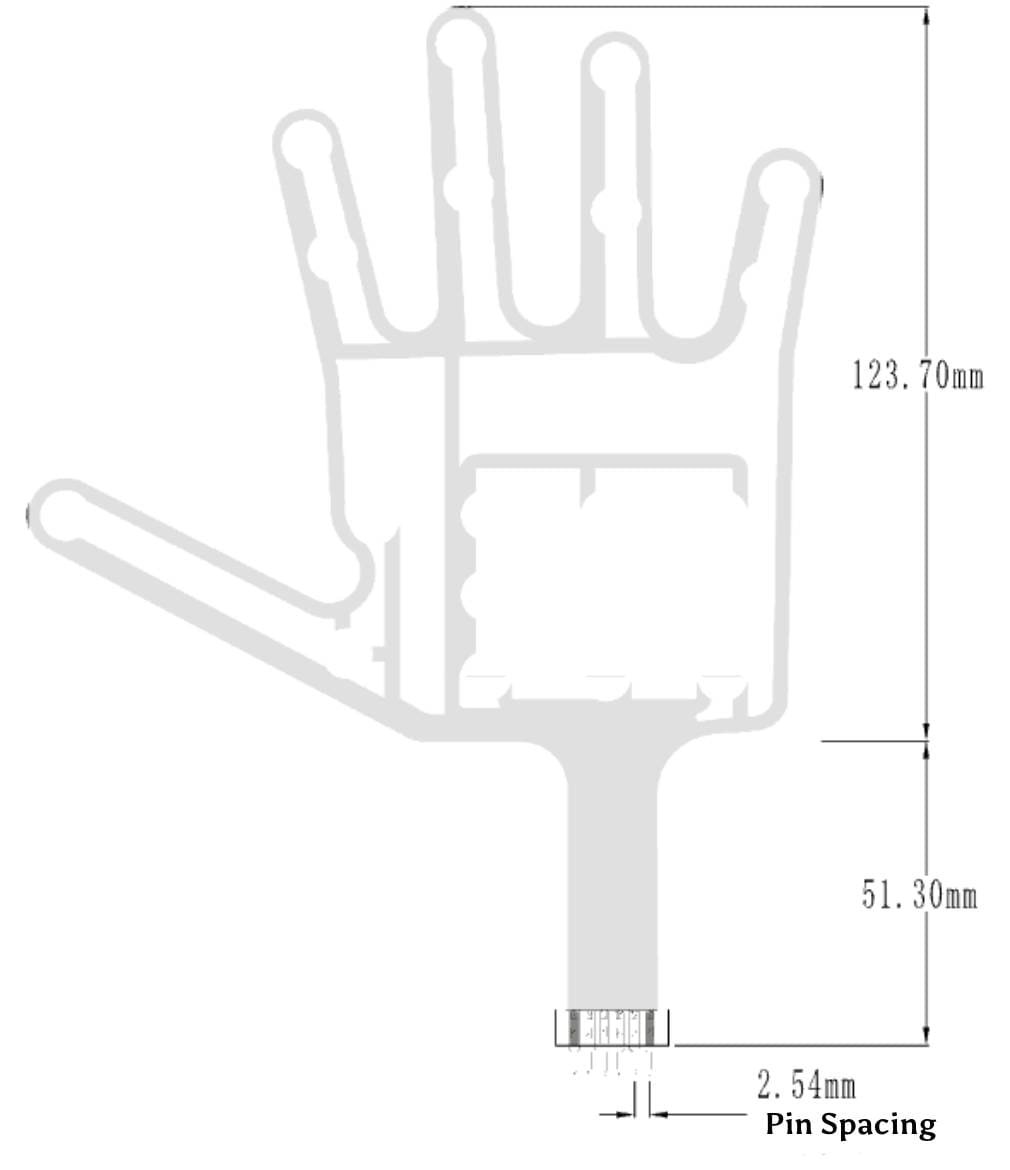

| Dimensions | |

| Logo | Size |

| Total Length | 175 mm |

| Width of Cable Layout | 51.3 mm |

| Sensitive Area | 20 x 6.6 |

| Pin Pitch | 2.54 |

| Tolerance | 0.2 |

| Performance Index | |

| Range | 0 – 5 kg |

| Thickness | <0.3 mm |

| Response Point | <100 g |

| Repeatability | +8.4%(50% loaded) |

| Consistency | +10% |

| Hysteresis | |

| Durability | >1 million times |

| Initial Resistance | 10 M (Non-Loaded) |

| Response Time | 1 millisecond |

| Resume Time | 15 milliseconds |

| Test Voltage | Typical Value DC 3.3 V |

| Operating Temperature | -20°C – 60°C |

| EMI | Nothing Produced |

| Electrostatic Discharge | Not Sensitive |

Notes:

- The response point is the moment when the pressure applied to the sensor gradually increases from 0. It is at this point that the sensor’s resistance decreases to a level below 1MΩ, indicating the initiation of a “response” from the sensor.

- The consistency between devices from different batches will exhibit a slight improvement. With calibration using a program algorithm, the consistency error can be effectively reduced to within a range of ±15%. This ensures a higher level of uniformity and accuracy across the devices, enhancing overall performance and reliability.

Instruction for Use:

When using the ZNS-01 flexible pressure sensor, it is important to follow these guidelines for optimal performance:

- Place the pressure-sensitive zone of the sensor on a firm, flat surface. Avoid using it on curved or irregular surfaces, as this can cause the sensor to be conductive even without pressure, affecting its response.

- When using the sensor on rigid and hard surfaces where the contact area exceeds the sensitive area, it may result in a small and unstable pressure response. To mitigate this, we recommend attaching a round soft rubber pad to the center of the sensitive area. The pad should have a diameter slightly smaller than the sensitive area, and its surface area should be at least 60% of the sensitive area. This ensures optimal performance and stability during pressure measurements.

- Use double-sided tape to securely fix the sensor on the supporting surface. Ensure that the surface is clean and tidy before applying the tape. We recommend using 3M brand double-sided tape, which provides reliable adhesion.

- Once pressure is applied to the sensor and held, there may be a slight drift in the output resistance value over time, usually within a 5% range. To minimize this error, timing calibration is recommended. During calibration, it is important to match the waiting time after applying pressure with the waiting time in actual applications.

Since the force state of the sensor can vary in different scenarios, we advise users to arrange the sensor according to their specific application needs. Conducting drift parameter testing tailored to their use case will help optimize the sensor’s performance and ensure accurate measurements.

By following these guidelines, you can ensure optimal performance and accuracy when using the ZNS-01 flexible pressure sensor.

Flexible Film Pressure Sensor ZNS-01

The revolutionary ZNS-01 flexible thin film pressure sensor represents a new era in sensing technology. With its cutting-edge design and independent intellectual property rights, this sensor utilizes flexible pressure sensing technology to deliver unparalleled performance.

The ZNS-01 sensor is printed on flexible and thin materials, boasting exceptional adhesion and unparalleled bending resistance. Combined with the use of high-sensitivity flexible nano functional materials, it achieves remarkable sensitivity in detecting pressure. This sensor is capable of delivering precise and accurate pressure measurements, making it ideal for a wide range of applications.

Operating as a resistive sensor, the ZNS-01 exhibits a decrease in output resistance as pressure is applied to its surface. This unique pressure-resistance relationship allows for reliable and accurate pressure detection. Whether it’s measuring subtle variations in touch pressure or detecting intense forces, the ZNS-01 sensor excels in providing high-sensitivity detection of pressure.

The applications for the ZNS-01 flexible film pressure sensor are vast and diverse. Its wide range of applications includes human-machine interaction, where it enables seamless and intuitive touch controls, enhancing user experience. Intelligent robots benefit from its precise pressure detection capabilities, allowing for better object manipulation and interaction. Additionally, this sensor finds extensive use in wearable devices, enabling pressure-sensitive functionalities for enhanced performance and convenience.

Not only that, but it also plays a crucial role in physiological health detection, providing valuable insights into various health-related parameters.

The ZNS-01 flexible film pressure sensor is a game-changer in the field of robotics, particularly as a tactile sensor for robots. Its exceptional sensitivity and flexibility enable robots to perceive and interact with their surroundings with remarkable precision and dexterity. Furthermore, it finds application in pressure detection on smart gloves, enhancing the capabilities of these gloves for various industries, including virtual reality, gaming, and industrial automation.

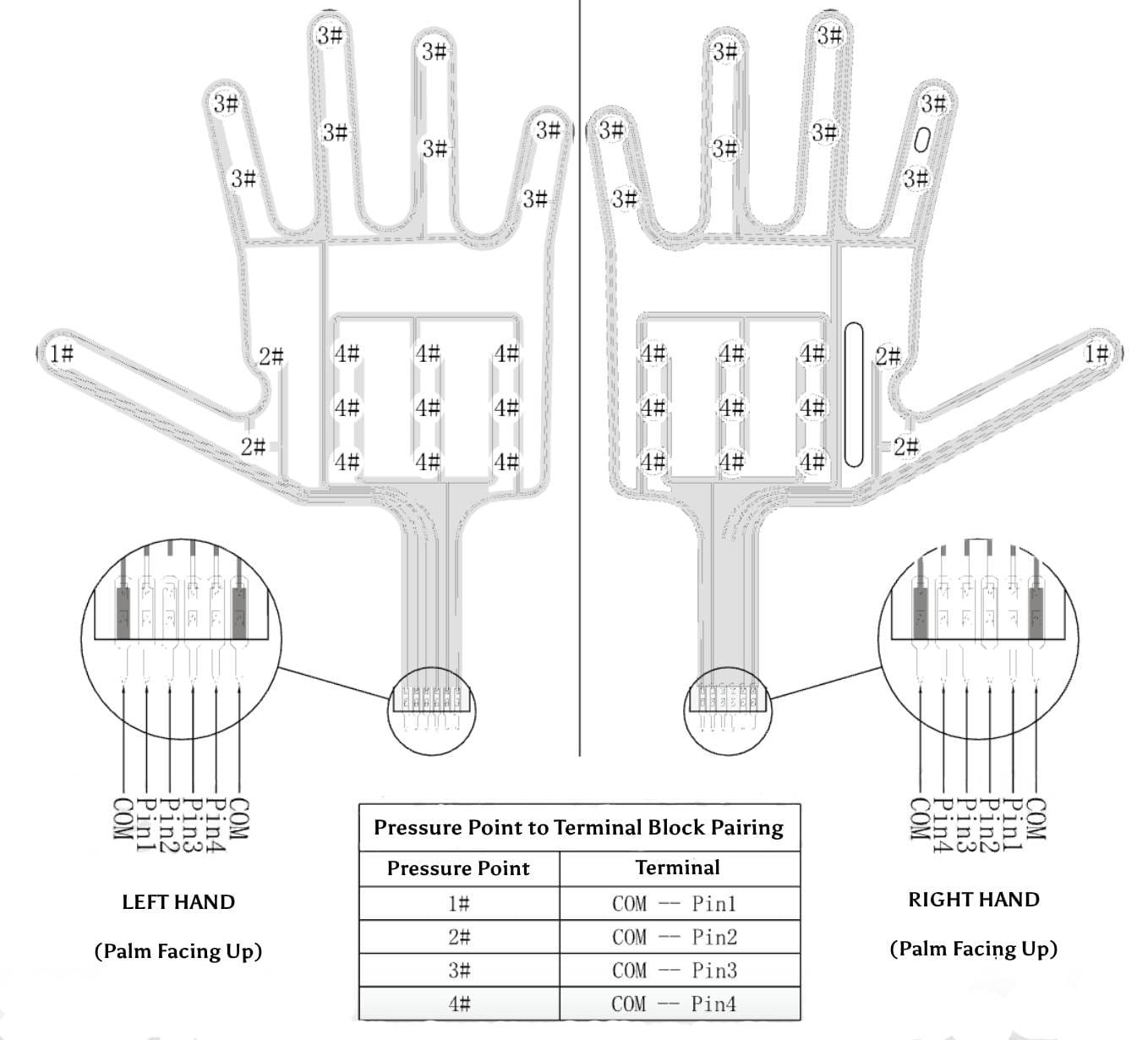

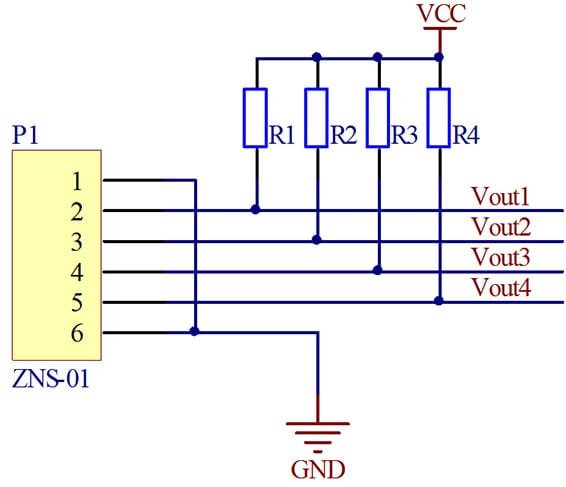

The brilliance of this circuit lies in its ability to consolidate multiple points by utilizing common terminals. Each sensor boasts 4 signal output ports, with pins #1 and #6 serving as shared terminals, facilitating efficient data transmission.

To determine the resistance value at the sensor’s sensitive point, meticulous calculations are performed using the measured Vout voltage value and the voltage divider resistance value. This invaluable information then paves the way for accurately calculating the corresponding pressure value by leveraging the pressure-resistance curve.

In situations where specific signal output impedance requirements arise, incorporating an operational amplifier circuit at the rear end of Vout proves to be a wise addition. This astute modification ensures optimal signal performance, meeting the unique demands of the application at hand.