Array Flexible Film Pressure Sensor MF-3216

Ultra-Thin

Large Detection Area

High Density Points

Wide Pressure Range

Fast Response Time

Customizable

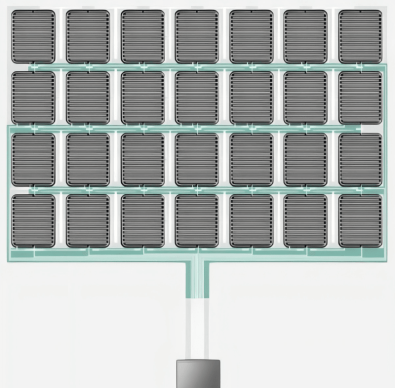

The Flexniss Array Sensor MF-3216 sets a new benchmark in ultra-thin, high-performance pressure sensing

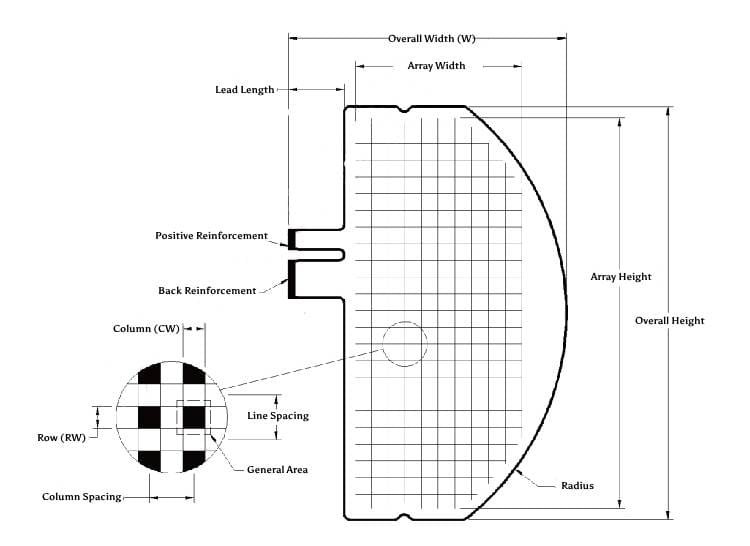

| Dimensions | |

| Overall Width | 250 mm |

| Overall Height | 371 mm |

| Lead Width | 50 mm |

| Radius | 234.5 mm |

| Array Width | 135.6 |

| Array Height | 316 mm |

| Row Width | 6 mm |

| Line Spacing | 10 mm |

| Number of Rows | 32 |

| Column Width | 5 mm |

| Column Spacing | 8.7 mm |

| Number of Columns | 16 |

| Total Pressure Points | 492 |

Interface Specifications

The sensor is built with two interfaces: the row and column interface.

The Row Interface is reinforced on the back and the contact electrode is on the front. Spacing is 1.0mm and it is recommended to use 32P-1.0mm-top connection FFC/FPC.

The Column Interface is reinforced on the front and the contact electrode is on the back. Spacing is 1.0mm and it is recommended 16P-1.0mm-downlink FFC/FPC.

| Pressure Range | |

| Effective Detection Range | 1Mpa |

| Maximum Pressure | 10Mpa |

The MF-3216 has undergone rigorous testing and has obtained RoHS certification. This signifies its compliance with international standards for environmental protection, assuring users of its quality and safety.

Array Flexible Film Pressure Sensor MF-3216

The Flexniss Array Sensor MF-3216 is an exceptional innovation in pressure sensing technology. With its remarkable features and customizable options, it offers precise and reliable pressure distribution mapping for a wide range of applications.

Ultra-Thin Design: With a film thickness not exceeding 0.6mm, the MF-3216 boasts an ultra-thin profile. This ensures minimal interference and enhanced flexibility, making it suitable for various applications where space is limited.

Large Effective Detection Area: The sensor’s impressive effective detection area enables accurate measurement of pressure distribution, even for foot pressure below 50 yards. This makes it ideal for applications such as gait analysis and foot pressure mapping.

High Pressure Point Density: The MF-3216 is equipped with 492 pressure points within its pressure-sensitive area, ensuring a high density of pressure detection. This allows for precise and detailed pressure mapping, enabling accurate analysis and assessment.

Fast Response Speed: With a response time of less than 1ms and a recovery time of less than 15ms, the MF-3216 exhibits exceptional responsiveness. This makes it perfect for high-speed dynamic scanning scenarios, ensuring real-time and accurate pressure measurements.

Wide Detection Pressure Range: The sensor offers a broad detection pressure range, with the capability to measure up to 1Mpa of pressure at a single point. This versatility allows for the monitoring of both subtle pressures and high-intensity forces.

Customizable and Versatile: Flexniss understands the unique requirements of different applications. The MF-3216 can be fully customized according to user needs, including overall dimensions, pressure point size and density, and pressure measurement range. This flexibility ensures seamless integration into various systems and applications.

The MF-3216 is a piezoresistive pressure sensor that operates based on the principle of converting an external pressure stimulus applied to the device into a measurable change in resistance.