In December 2023, Tesla released a video showcasing Optimus Gen2, a robot with remarkable precision in tasks like grasping and passing eggs. The highlight of Optimus Gen2 is its tactile sensors embedded in each fingertip, which provide exceptional control, perception, and gripping abilities. This underscores the importance of tactile sensors in humanoid robots. Let’s delve into their principles, market potential, and applications.

The Role of Tactile Sensors in Humanoid Robots

Like humans, robots rely on tactile feedback to sense, perceive, and make decisions, enhancing their understanding and interaction with the environment. Compared to visual feedback, tactile feedback offers better insights into material properties and object details, crucial for accurately determining shape, contact force, and direction.

Without tactile feedback, robots are prone to inaccuracies, instability, and clumsy interactions, making them unsuitable for delicate and complex tasks. As AI technology advances and humanoid robots become more prevalent, the need for tactile perception has become essential.

Tactile sensors help robots perceive environmental interactions, detecting contact force, temperature, humidity, vibration, and material properties. Larger contact areas on tactile sensors gather more information, and higher resolution in sensor arrays ensures precise data.

Flexible Tactile Sensors: An Overview

1.1 Definition and Characteristics

Flexible tactile sensors use flexible materials to convert mechanical pressure into electrical signals, enabling tactile perception. They are known for high sensitivity, flexibility, fast response, and the ability to bend and fold.

These sensors can be categorized into piezoresistive, piezoelectric, capacitive, optoelectronic, magneto-sensitive, optical fiber, and ultrasonic types. Capacitive, piezoresistive, and piezoelectric sensors are the most common, with capacitive sensors leading the market at 54.6%.

Flexible tactile sensors are made from sensitive materials (such as semiconductors, organic polymers, carbon nanotubes, and graphene) and flexible substrates (like silicone rubber and polydimethylsiloxane or PDMS). For example, XELA Robotics’ uSkin product, used in robots, features a silicone rubber base.

Equipping all five fingers of a robotic hand with multi-array flexible tactile sensors made of silicone rubber costs around $812.

1.2 Market Potential

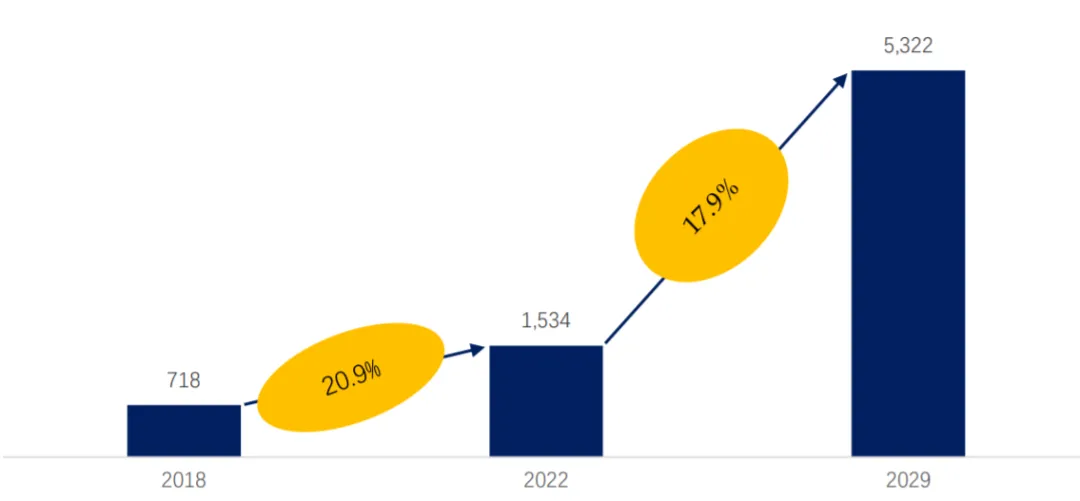

According to QYResearch, the global market for flexible tactile sensors is expected to reach $5.32 billion by 2029, with a compound annual growth rate (CAGR) of 17.9%.

As new materials and processes develop, tactile sensors are becoming more flexible, lightweight, and sensitive, expanding their applications. Besides robotics, these sensors are used in industrial equipment, medical devices, consumer electronics, sports equipment, textiles, aerospace, and environmental surveying.

Major global manufacturers include Novasentis, Tekscan Inc., Japan Display Inc. (JDI), Baumer Group, Fraba Group, Syntouch, Canatu, Sensel, FORCIOT, and TDK Shenzhen Technology Co., Ltd. In 2022, the top five companies held about 57.1% of the global market.

Conclusion

Flexible tactile sensors are enhancing humanoid robots’ capabilities, enabling precise and complex tasks. As technology advances, their applications will expand, driving growth in various industries. The market for these sensors is set for rapid expansion, presenting opportunities for innovation in robotics and beyond.