Pressure Sensor Testing: The Secret to Accurate Performance

Pressure sensors play a crucial role in various industries, from aerospace and automotive to manufacturing and healthcare. These sensors are designed to measure and monitor pressure levels in different applications, ensuring safety, accuracy, and efficiency. However, to achieve precise and reliable readings, pressure sensor testing is essential.

In this article, we will delve into the significance of performance testing and explore the key factors that contribute to accurate pressure measurements.

The Importance of Pressure Sensor Testing

Performance testing is a critical step in the development and evaluation of pressure sensors. It involves subjecting the sensors to controlled conditions and analyzing their response to different pressure levels. By conducting rigorous performance tests, manufacturers can ensure that the sensors meet the required specifications and perform optimally in real-world applications.

Accuracy and Sensitivity

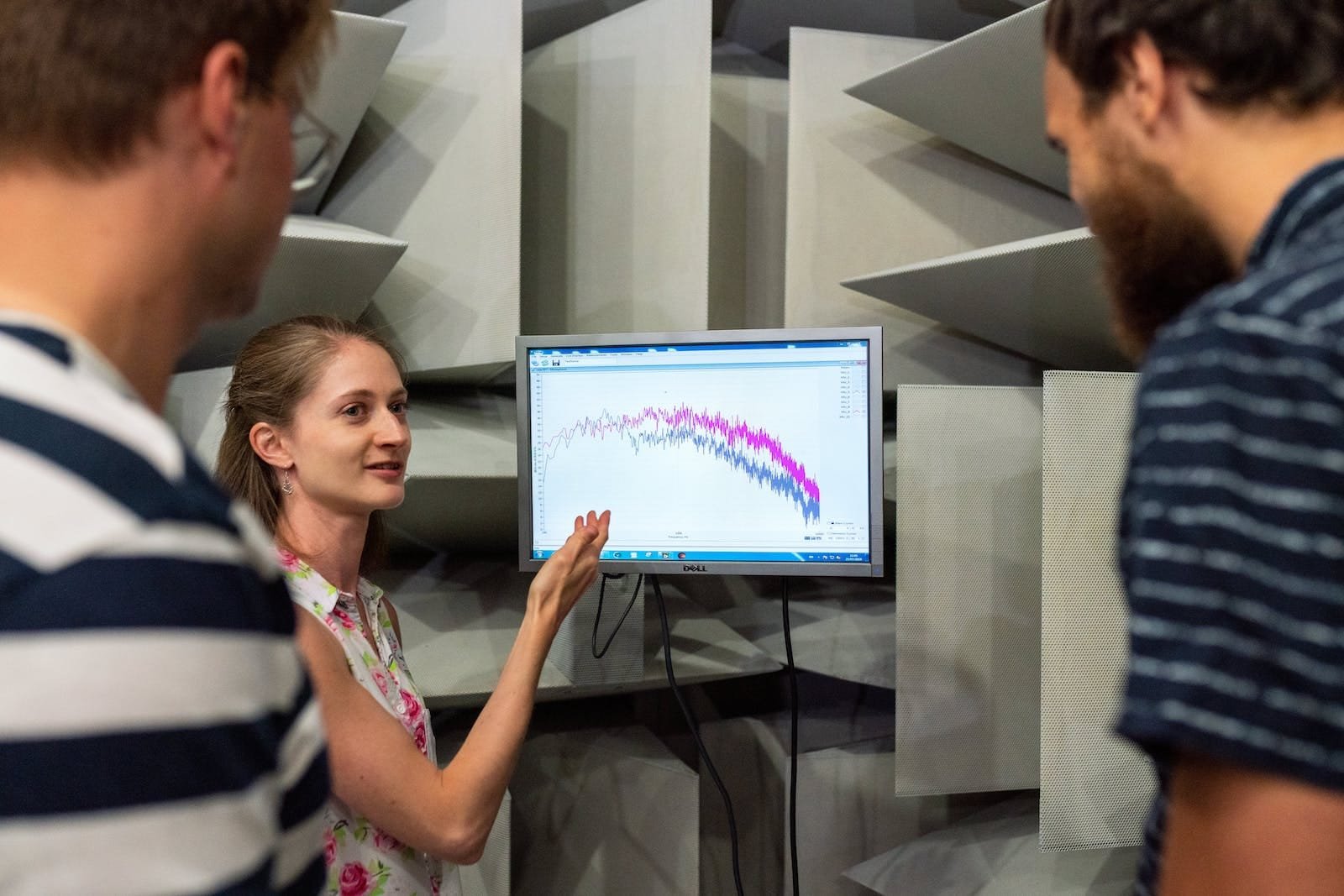

One of the primary objectives of pressure sensor testing is to evaluate accuracy and sensitivity. Accuracy refers to how closely the sensor’s output matches the true pressure value. Sensitivity, on the other hand, measures the smallest change in pressure that the sensor can detect. Both accuracy and sensitivity are crucial for obtaining reliable and precise readings.

During performance testing, the sensor is subjected to a range of known pressures, and its output is compared to the reference values. This allows manufacturers to determine the sensor’s accuracy by calculating the percentage error. Additionally, sensitivity can be evaluated by measuring the smallest detectable pressure change that produces a noticeable output change from the sensor.

Linearity and Hysteresis

Linearity and hysteresis are two other important factors that impact pressure sensor performance. Linearity refers to how well the sensor’s output follows a straight line in response to changes in pressure. A perfectly linear sensor will have a consistent output proportional to the applied pressure. However, in reality, non-linearities can occur due to various factors, such as manufacturing tolerances or sensor design.

Hysteresis, on the other hand, refers to the difference in sensor output when pressure is increased and then decreased back to the original value. A high-quality pressure sensor should exhibit minimal hysteresis, indicating that its output is not affected by the previous pressure conditions. Performance testing helps identify any non-linearities or hysteresis effects, allowing manufacturers to make necessary adjustments to improve the sensor’s performance.

Temperature Compensation

Temperature can significantly affect the performance of pressure sensors. Changes in temperature can lead to variations in sensor output, resulting in inaccurate readings. Therefore, performance testing often includes temperature compensation evaluations. The sensor is subjected to different temperature conditions while the pressure remains constant. This allows manufacturers to assess the sensor’s ability to compensate for temperature variations and provide accurate readings across a wide temperature range.

Stability and Longevity

Flexniss: Helping You Deliver Precise Sensor-Based Tech to the World

Pressure sensor testing is a critical aspect of ensuring accurate and reliable pressure measurements. By evaluating accuracy, sensitivity, linearity, hysteresis, temperature compensation, stability, and longevity, manufacturers like you can develop high-quality sensors that meet the stringent requirements of different industries.

Through rigorous performance testing, you can identify any shortcomings in sensor performance and make necessary improvements. This, in turn, leads to more precise and trustworthy pressure readings, enabling industries to achieve better control, safety, and efficiency in their operations. As pressure sensor technology continues to advance, performance testing remains an indispensable ingredient in the pursuit of precision and reliability.

Get in touch with Flexniss today or browse through our catalog to find more information about our pressure sensor testing modules!