Flexible Thin Film Pressure Sensor SF-15

Extremely Thin

Strong Bending Resistance

Swift Response

Long Life

Easy Signal Detection

Multi-Touch, Single Point Detection

Discover the resilience and precision of the 0.30mm SF15 flexible sensor, engineered for durability and accurate pressure detection. This exceptional sensor has proven its reliability through extensive testing, enduring over 1 million cycles while maintaining peak performance.

Thanks to its unique design, the SF15 establishes a distinct pressure-resistance relationship, enabling precise pressure detection. As pressure is applied to its surface, the sensor’s resistance decreases, ensuring accurate and consistent measurements. Rely on the longevity and precision of the SF15 for all your sensing requirements.

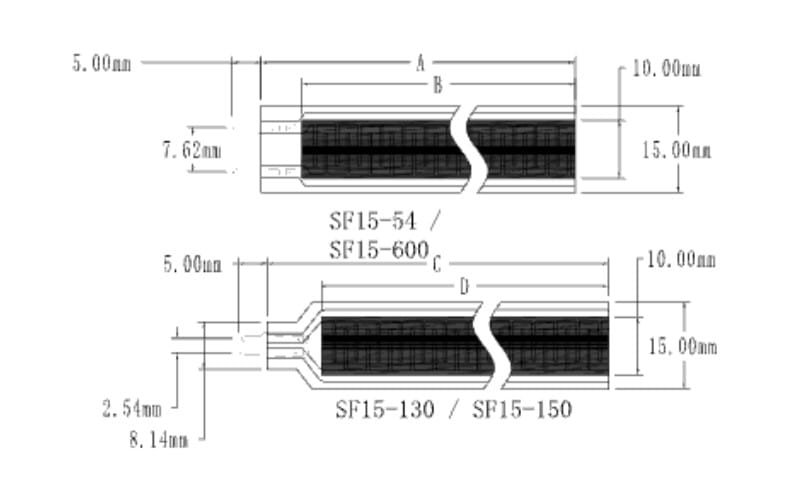

| Product Dimensions | ||||

| Logo | SF 15-54 | SF 15-130 | SF 15-150 | SF 15-600 |

| Length | 59 mm | 135 mm | 155 mm | 605 mm |

| Width | 15 mm | |||

| Pin Pitch | 7.62 | 2.54 | ||

| Tolerance | 0.2 | |||

| Sensitivity Area | 47*10 | 120*10 | 140*10 | 593*10 |

| Performance Index | ||||

| Model | SF 15-54 | SF 15-130 | SF 15-150 | SF 15-600 |

| Range | 0-5 kg | |||

| Thickness | <0.35 mm | |||

| Response Point | 50 g | |||

| Repeatability | <+10% (60% loaded) | |||

| Consistency | +15% Batch of the same model | |||

| Hysteresis | +15% (RF+ – RF-)/RF+ | |||

| Durability | >1 million times | |||

| Initial Resistance | >10MΩ (Non-Loaded) | |||

| Response Time | <1 ms | |||

| Resume Time | <15 ms | |||

| Test Voltage | Typical Value DC 3.3V | |||

| Operating Temperature | -20°C-60°C | |||

| EMI | Nothing Produced | |||

| ESD | Not Sensitive | |||

Notes:

- The sensor’s response point is defined as the moment when pressure starts increasing from 0, coinciding with a resistance drop below 1MΩ. This critical threshold marks the beginning of the sensor’s detection and signifies the initiation of pressure measurement.

- Calibration using the program algorithm is necessary before use as there maybe slight inconsistencies between batches. This calibration process minimizes the consistency error by 15% guaranteeing precise and dependable performance across applications.

Flexible Thin Film Pressure Sensor SF-15

The SF15 is a flexible film pressure sensor incorporating cutting-edge technology and proprietary intellectual property rights in flexible pressure sensing. This sensor utilizs flexible and thin materials, integrating highly adhesive and bend-resistant nano functional materials with exceptional sensitivity, enabling precise and practical detection of pressure.

Operating as a resistive sensor, the flexible film pressure sensors exhibit changes in output resistance corresponding to the applied pressure on the sensor surface. By employing a specific pressure-resistance relationship, this sensor effectively measures pressure and finds extensive utility in smart homes, automotive electronics, smart robots, medical beauty, and other relevant domains. Notably, they excel in detecting and measuring pressure on flexible curved surfaces.

The SF series encompasses various product models such as SF15-54, SF15-130, SF15-150, SF-600, each catering to diverse requirements and applications.

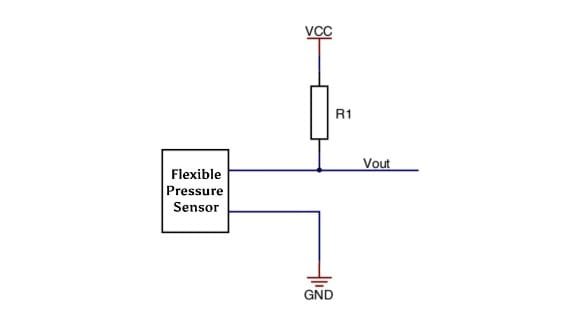

The SF15 reference circuit utilizes partial pressure measurement. It involves connecting the pressure sensor in series with resistor R1, with one end connected to VCC and the other end connected to GND, forming a basic voltage divider circuit. The voltage obtained from the division is then connected to Vout.

This circuit allows the sensor’s output resistance change, which corresponds to the pressure variation, to be converted into a voltage change signal. To cater to different application requirements, it is recommended to select an appropriate load resistance R1 ranging from 1kΩ to 100kΩ. It is suggested that the load resistance be set to 50% of the range pressure corresponding to the sensor’s resistance value.

Vout can be connected to a single-chip microcontroller’s ADC interface to detect pressure levels. Furthermore, the MCU’s external interrupt IO interface can be utilized as a pressure trigger function.

Instruction for Use:

When using the SF15 flexible pressure sensor, it is important to follow these guidelines for optimal performance:

- Place the pressure-sensitive zone of the sensor on a firm, flat surface. Avoid using it on curved or irregular surfaces, as this can cause the sensor to be conductive even without pressure, affecting its response.

- When using the sensor on rigid and hard surfaces where the contact area exceeds the sensitive area, it may result in a small and unstable pressure response. To mitigate this, we recommend attaching a round soft rubber pad to the center of the sensitive area. The pad should have a diameter slightly smaller than the sensitive area, and its surface area should be at least 60% of the sensitive area. This ensures optimal performance and stability during pressure measurements.

- Use double-sided tape to securely fix the pressure sensor on the supporting surface. Ensure that the surface is clean and tidy before applying the tape. We recommend using 3M brand double-sided tape, which provides reliable adhesion.

- Once pressure is applied to the sensor and held, there may be a slight drift in the output resistance value over time, usually within a 5% range. To minimize this error, timing calibration is recommended. During calibration, it is important to match the waiting time after applying pressure with the waiting time in actual applications.

Since the force state of the sensor can vary in different scenarios, we advise users to arrange the sensor according to their specific application needs. Conducting drift parameter testing tailored to their use case will help optimize the sensor’s performance and ensure accurate measurements.

By following these guidelines, you can ensure optimal performance and accuracy when using the SF15 flexible pressure sensor.